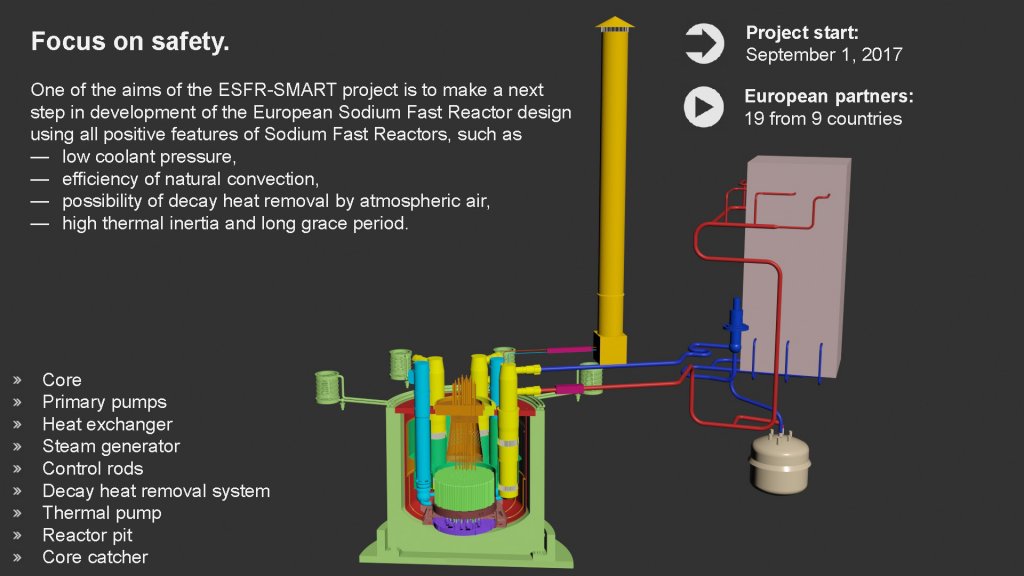

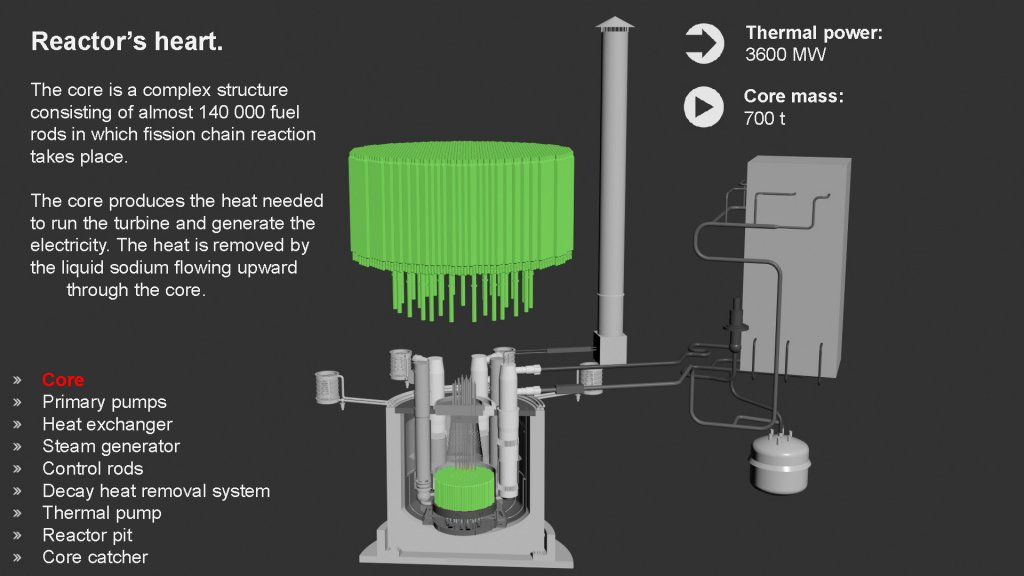

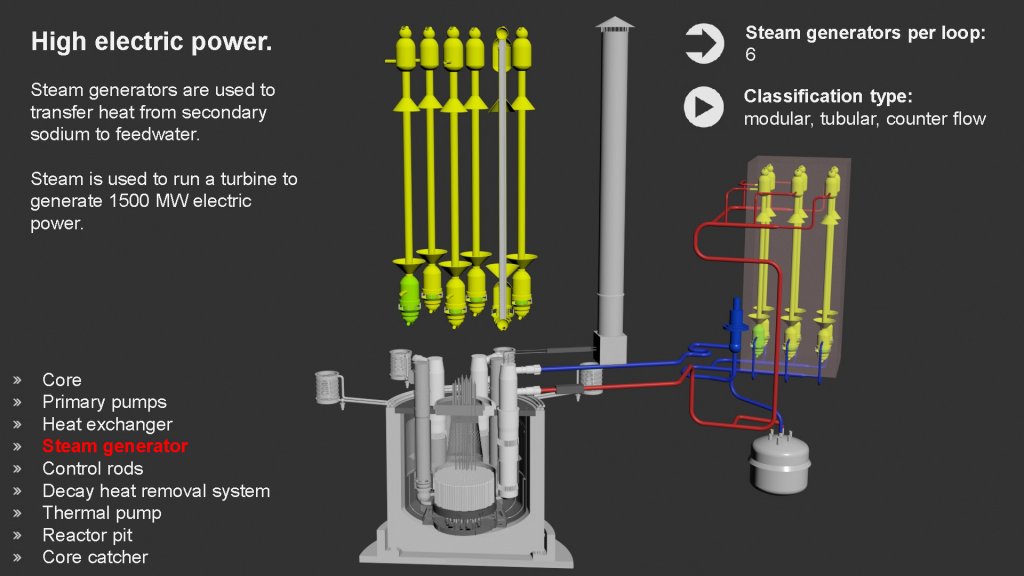

The project will take the large-power (1500 MWe / 3600 MWt) sodium cooled fast reactor concept a step further, using the outputs of the SPX2, EFR and CP-ESFR projects and using the Generation-IV International Forum objectives as a target.

Compared to the traditional traditional light water reactors (LWRs) and sodium fast reactors (SFRs), the new reactor should be able to reprocess its own and legacy waste, exclude fuel enrichment, be more reliable in operation, more environmentally-friendly, more affordable, and better protected against proliferation. Last but not least: the new reactor should be safer than traditional LWRs and SFRs. The implementation of this new safety level in the ESFR reactor concept is one of the main challenges that will tackled in the project.

How will this be achieved?

Using the CP-ESFR legacy as a starting point, the project will select novel safety measures and technically assess their impact on the ESFR defence-in-depth levels. The higher level of safety compared to traditional LWRs and SFRs will be demonstrated through two examples:

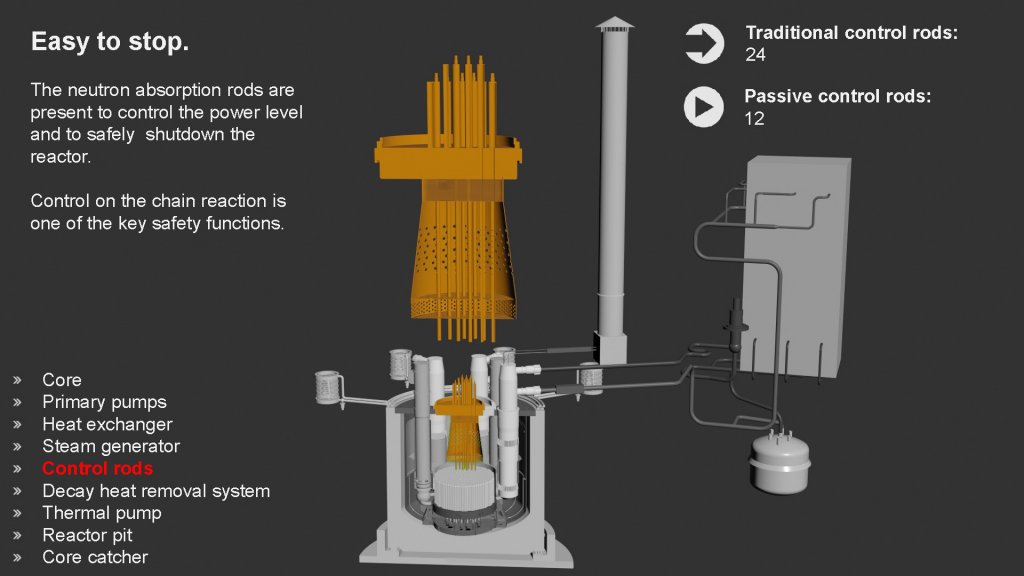

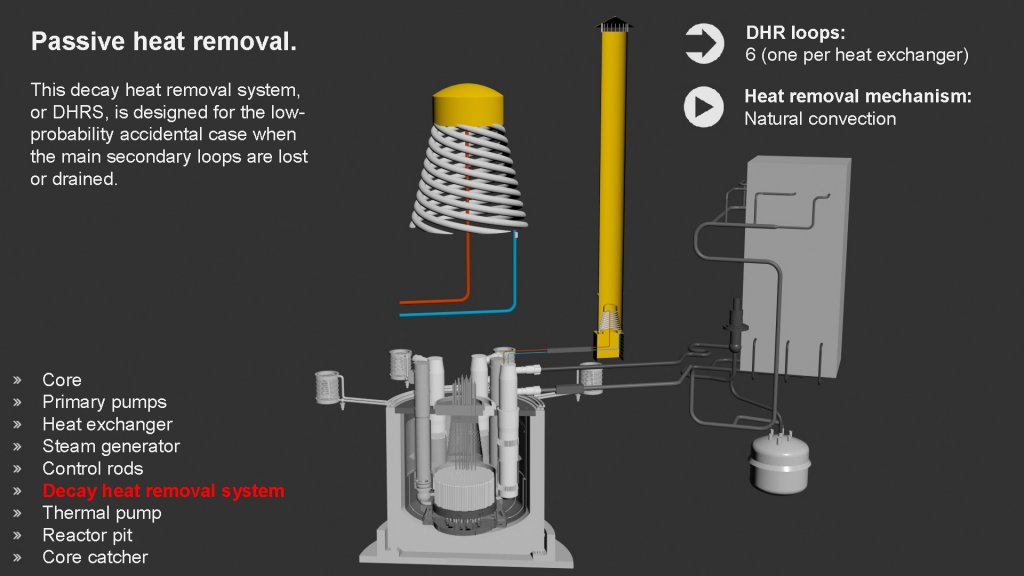

- hydrogen explosions and core meltdown in a Fukushima-like accident will be impossible in the new reactor

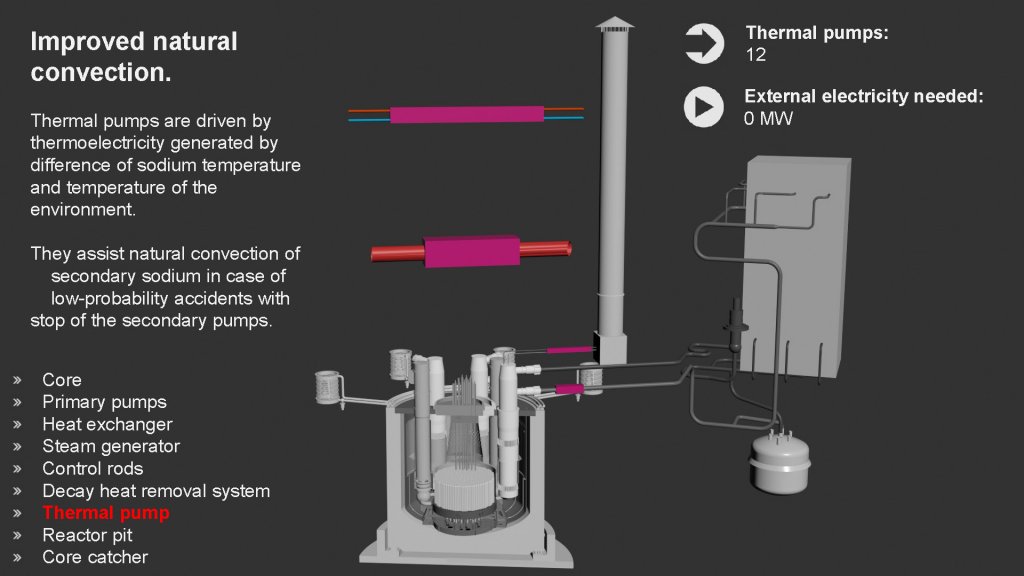

- the grace time between the sodium boiling onset and the core melting onset will significantly increase (at least up to several minutes), which will allow the activation of passive mitigation dispositions

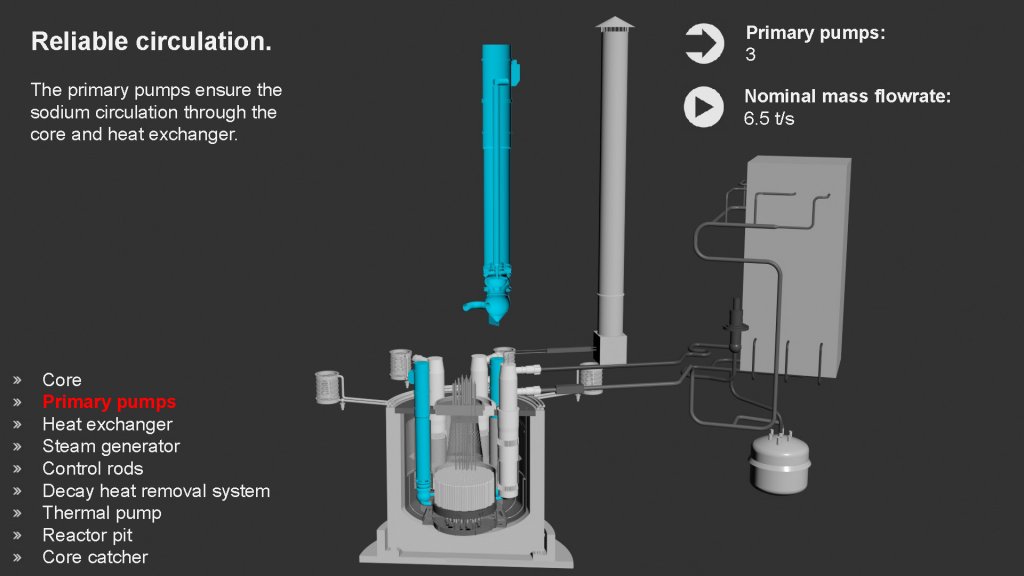

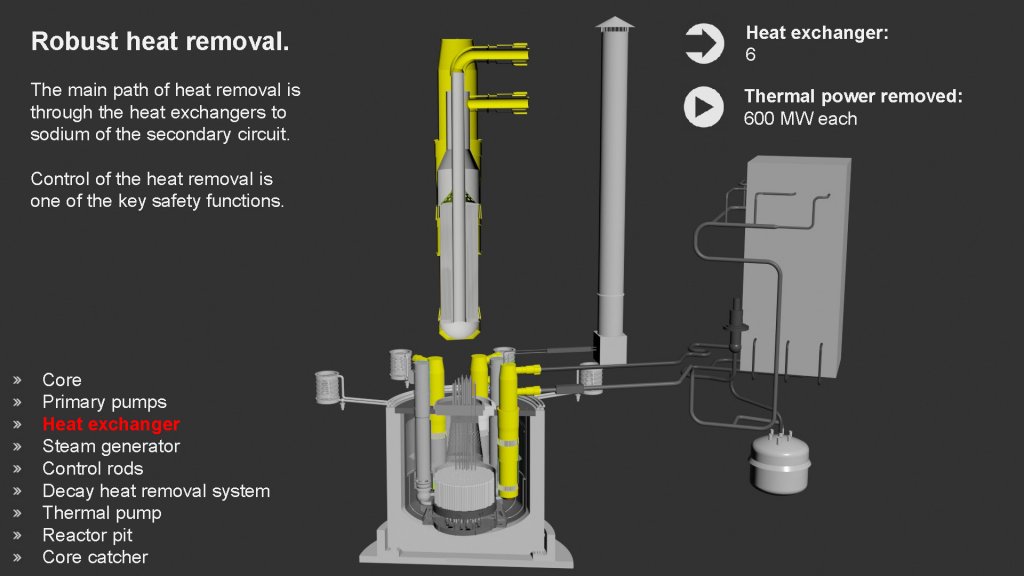

The first enhancement will be reached by improving the passive decay heat removal capabilities, while the second one—by implementing the innovative low-void core design. To make these demonstrations more convincing, the analytical assessments will be supported and complimented when necessary by the new experiments and measurements, as well as by analysing the relevant legacy data again.

The new knowledge will be made available for exploitation beyond the ESFR-SMART project. An important aspect of this concept is the dissemination, education and training activities. In particular, the project will link the network of the European sodium facilities with the network of the PhD studies by awarding mobility grants that will allow students to carry out part of their work at one of the sodium facilities and to participate in a real experiment.

The methodology

The overall methodology includes experimental methods, calibration and validation methods and safety assessment methods. New educational methodology will also be developed. The project is structured in three R&D steps.