Standing for Jet Impingement on the Metallic Core Catcher, the JIMEC test is a unique and large-scale experiment belonging to the WP2.2.3 of the ESFR-SMART project and originally named as MOCKA test.

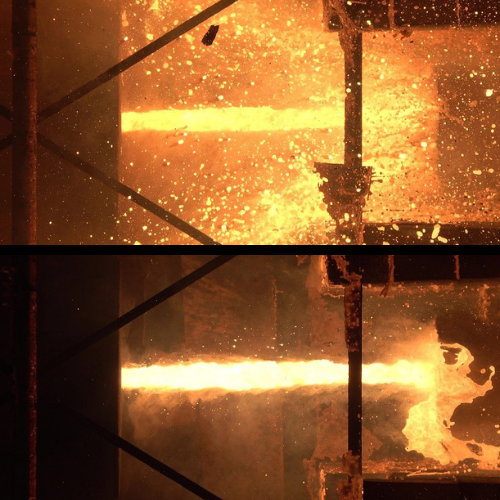

JIMEC-I test was successfully performed on the 11th July 2019. With a jet diameter of 40 mm, and jet temperature of about 2100°C, the 40 cm substrate was ablated through the bottom in 31 seconds. Pool effect was clearly detected during the course of the ablation. This is the first ever test on the ablation of a thick steel substrate with a high temperature, high-velocity steel jet.

The prototypical test data provided insights to a wide application range within and also beyond the nuclear safety research. The JIMEC-II test is planed in September 2019 with another jet diameter.

A test for what?

Dedicated to the Severe Accident Group (SAR) at the Institute of Nuclear and Energy Technology (IKET), Karlsruhe Institute of Technology, JIMEC tests are designed firstly to create a metallic jet with stainless steel composition and with designed superheat and fall height; and secondly to record the ablation process of a 40 cm thickness substrate of the same material composition as the jet. The mass of the metallic melt is 1000 kg, and the jet velocity at the substrate surface is about 5 m/s.

Two tests are planned with the variation in one jet parameter to quantify its influence on the ablation dynamic, and especially on the beneficial pool effect, during which the ablation velocity is reduced. The metallic jet is generated with the thermite reaction. Among many technical challenges are the creation of the exact stainless composition with 18 wt. % Cr and 10 wt. % Ni, the instrumentation of a dense array of thermocouples in the substrate to record the ablation velocity, and the whole safety and logistic measures of the open-air performance.

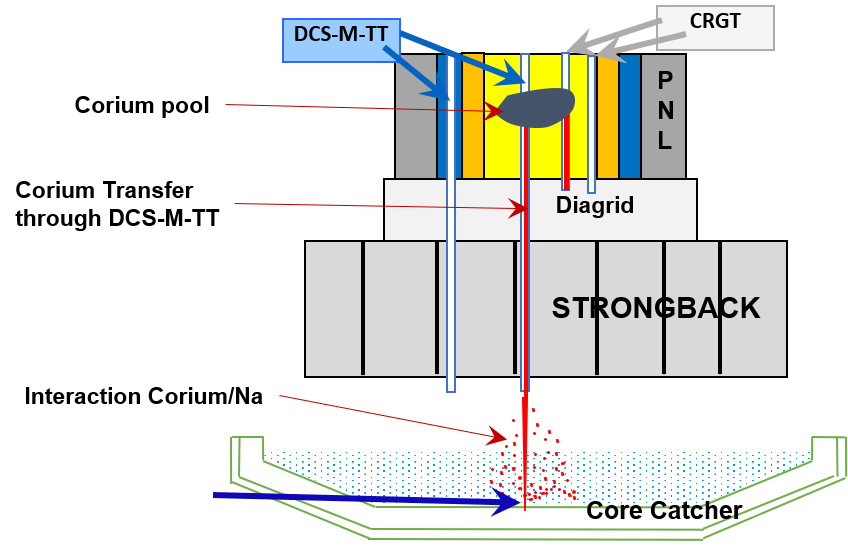

The JIMEC test aims to provide prototypical experimental data to quantify the In-Vessel Core-Catcher material adopted in the ASTRID reactor design. In course of a less probably accident that a corium pool builds up in the core region, dedicated corium relocation measure with Corium Transfer Tubes (DCS-M-TT) will minimise the core melt mass in the core region to avoid recriticity. Due to many reasons, metallic core catcher is inclined to collect the relocated corium (see graphic below).

A great safety concern is the impingement of a high-temperature and high-momentum corium jet through DCS-M-TT on the metallic core catcher material. Although both oxide corium and metallic corium can be relocated, metallic corium is considered to be more crucial on the core catcher ablation process due to its low solidifying temperature and therefore the less potential to build up a protecting crust layer.