Guillaume Révy is the first student who has benefited from the ESFR-SMART student mobility program. He spent eight weeks in Riga (May to July 2019), at the Institute of Physics of University of Latvia (IPUL), and worked on the design of a sodium purification line in the framework of a new test loop.

During my first year of master degree, I completed an eight-week internship at the Institute of Physics University of Latvia (IPUL) in the framework of the ESFR-SMART student mobility program. This Institute is based in the cosmopolitan and culturally rich city of Riga, located on the edge of the Baltic Sea. Despite its small population, Latvia is active in scientific research and is increasingly involved in international projects. Among its many laboratories, one of them studies the magneto-hydrodynamic (MHD) aspects of sodium: the laboratory of MHD Technology. Since sodium is the area of expertise of the French Alternative Energies and Atomic Energy Commission (CEA) where I am completing my education, this internship was a great opportunity for both myself and the laboratory of MHD Technology.

More specifically, the sodium used in the test loops can contain various impurities in its volume including, in particular, oxygen and hydrogen. There are several risks inherent to these impurities: corrosion of materials, plugging of narrow gaps, fouling of heat exchangers…. Therefore purification is a required process in sodium tests facilities. In the frame of the production of a new test loop, I worked on the design of a sodium purification line with the help of 4 people: Leonids Buligins (Director, Institute of Physics), Kalvis Kravalis (Senior researcher), Oskars Mikanovskis (Technician) and Arturs Brekis (PhD student).

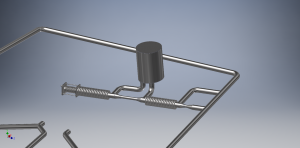

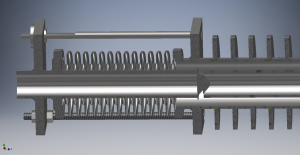

Purification systems, including cold traps, is a technology used since the first generation of Sodium-cooled Fast Reactor (SFR). Its particular design enables to crystallise, thanks to a temperature variation, dissolved oxygen and hydrogen to produce sodium oxide and sodium hydride on internal structures. On the basis of research articles, first drafts and interviews with the different actors of the project, I realised a 3D model using the software AutoCad Inventor. Then, I drafted the parts in preparation for their manufacture in the laboratory workshop. The purification system is composed of two rows of heat exchangers, one cold trap and one modular plugging.

3D model realised with AutoCad Inventor.

To conclude, I thank warmly IPUL for integrating me in their research team and enabling me to expand my knowledge on sodium technologies. I had the opportunity to work with inspiring people and I am proud to have been able to contribute to the projects of this Institute.